Regulations for ventilation systems

With the aim of consuming as little energy as possible, while achieving optimal comfort inside buildings, the dual flow ventilation system comes into play, achieving these objectives in a simple and straightforward manner.

This system allows us to achieve significant savings on the electricity bill due to its exceptional performance, saving a large part of the energy. Its effectiveness ensures compliance with the corresponding energy regulations, which year after year set challenges related to CO2 emissions in an attempt to prevent or curb climate change.

Thanks to the design of this system, significant energy savings can be made in both summer and winter. Below, we explain the operation of these ventilation systems, and how to maximize their performance during installation, which may present acoustic problems.

Technical Building Code (CTE)

The Technical Building Code is the regulatory framework that specifies and collects the security and habitability requirements that buildings must meet as established in Law 38/1999 of November 5, on the Organization of Building (LOE).

In addition to being responsible for establishing these basic rules of security and habitability such as energy savings, health regulations, and structural and fire safety, the CTE also focuses on safeguarding universal accessibility and non-discrimination in access to buildings. These responsibilities are assumed with the objectives of pursuing continuous improvement in the sustainability of buildings and their quality for users.

The role assumed by this organization in urban development is merely prescriptive, since while the requirements that buildings must meet are defined, it does not strictly define how these objectives of security and habitability should be achieved. This nuance favors innovation in engineering and architecture, as designers and builders have the opportunity to approach building within a framework that establishes guidelines but does not define how that development should take place.

Technology and research are key components in establishing new ways of building, without losing sight of traditional know-how and facilitating the progressive and continuous improvement of structures. Companies like Siber leverage this regulatory framework to rely on the basic principles of construction and propose innovative and sustainable solutions, achieving an improvement in the air quality for tenants and in the energy efficiency of buildings.

The CTE develops its regulations through a series of Basic Documents (DB), which outline the main characteristics that buildings must meet concerning fire safety, energy savings, or health regulations. Ventilation systems are a fundamental element in the construction and rehabilitation of housing, and Siber has always sought to adapt its development to the current regulations in the most efficient and innovative way. These are the most noteworthy Basic Documents for ventilation systems and networks.

Basic Document HS3 - Habitability and Health - Indoor Air Quality

Generalities

Scope of application

This section applies to residential buildings, inside them, the waste storage rooms, storage rooms, parking lots, and garages; and, in buildings for any other use, to parking lots and garages. It is considered that the areas for vehicle circulation are part of the parking lots and garages.

For premises of any other type, it is considered that the basic requirements are met if the conditions established in the RITE are observed.

Verification procedure

For the application of this section, the sequence of verifications outlined below must be followed.

- Compliance with the established conditions for the flow rates in section 2.

- Compliance with the design conditions of the ventilation system in section 3:

- For each type of premises, the type of ventilation and the conditions related to the means of ventilation, whether natural, mechanical, or hybrid;

- The conditions relating to the following construction elements:

- openings and ventilation mouths;

- inlet ducts;

- extraction ducts for hybrid ventilation;

- extraction ducts for mechanical ventilation;

- hybrid fans, mechanical fans, and extractors;

- windows and exterior doors.

- Compliance with the sizing conditions in section 4 relating to the construction elements.

- Compliance with the conditions of construction products in section 5.

- Compliance with construction conditions in section 6.

- Compliance with the maintenance and conservation conditions in section 7.

Characterization and quantification of requirements

In the habitable premises of homes, a sufficient flow of exterior air must be provided to ensure that in each premises, the annual average concentration of CO2 is less than 900 ppm and that the annual accumulation of CO2 exceeding 1,600 ppm is less than 500,000 ppm.h, in both cases with the design conditions of appendix C.

Additionally, the provided flow of exterior air must be sufficient to eliminate pollutants not directly related to human presence. This condition is considered met with the establishment of a minimum flow of 1.5 l/s per habitable premises during periods of non-occupation.

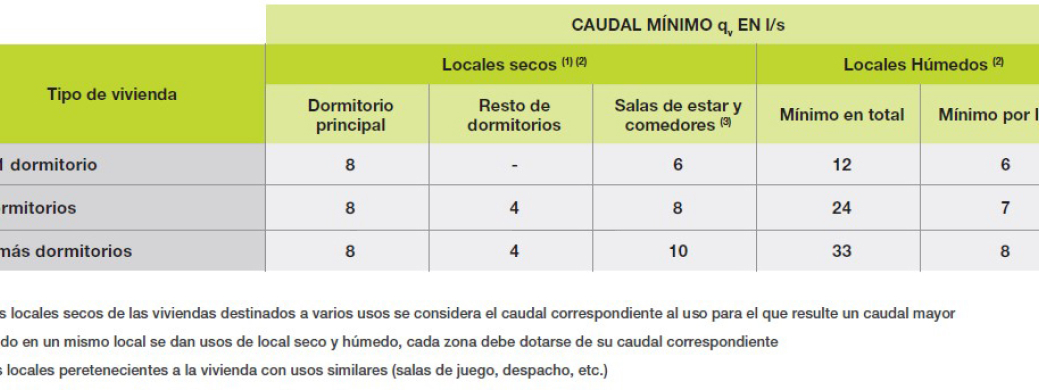

The two previous conditions are considered satisfied with the establishment of constant flow ventilation according to table 2.1.

Table 2.1. Minimum flows for constant flow ventilation in habitable premises

In the cooking area of kitchens, a system must be available to extract pollutants produced during its use, independently of the general ventilation of the habitable premises. This condition is considered satisfied if a system is available in the cooking area that can extract a minimum flow of 50 l/s.

For non-habitable premises included in the scope of application, at least the sufficient flow of exterior air must be provided to eliminate pollutants specific to the use of each premises. In the case of storage rooms, their common areas, and waste storage, the main pollutants are humidity, odors, and volatile organic compounds. In the case of parking lots and garages, they are carbon monoxide and nitrogen oxides.

This condition is considered satisfied if the ventilation system is capable of establishing at least the ventilation flows of table 2.2., whether through constant flow ventilation or variable flow ventilation controlled by presence detectors, pollutant detectors, timer programming, or other types of systems.

Table 2.2. Minimum ventilation flows in non-habitable premises.

Design

General conditions for ventilation systems

Housing

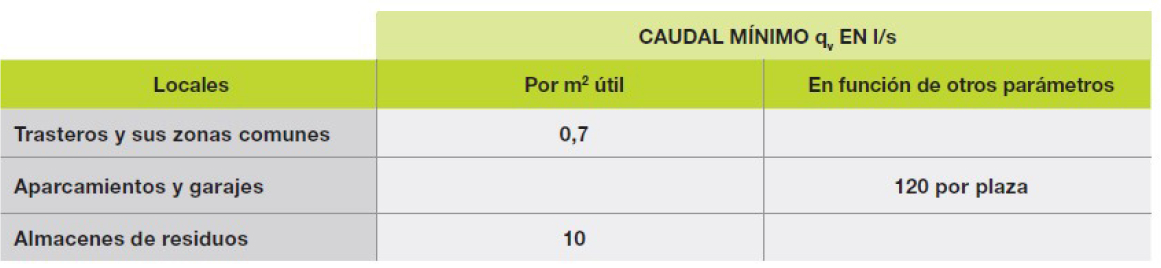

Homes must have a general ventilation system that can be hybrid or mechanical with the following characteristics (see examples in figure 3.1):

The air must circulate from dry premises to humid ones; thus, living rooms, bedrooms, and lounges must have intake openings; toilets, kitchens, and bathrooms must have extraction openings; partitions located between rooms with intake and those with extraction must have passage openings.

Rooms with several uses as mentioned above must have the corresponding openings in each area designated for a different use.

As intake openings, openings equipped with air vents or fixed openings in the joinery must be provided, such as micro-ventilation devices with air permeability according to UNE EN 12207:2000 in the opening position of class 1 or higher; however, when the exterior joinery is class 1 in air permeability according to UNE EN 12207:2000, the opening joints can be considered as intake openings.

When the ventilation is hybrid, the intake openings must connect directly to the outside. Air vents must be located at a height greater than 1.80 m from the ground.

When any area with extraction is partitioned, passage openings must be provided between the compartments; the extraction opening must be in the most contaminated compartment, which, in the case of toilets and bathrooms, is the one where the toilet is located, and in the case of kitchens, it is where the cooking zone is located; the passage opening connecting with the rest of the dwelling must be located in the least contaminated area.

The extraction openings must connect to extraction ducts and must be located at a distance from the ceiling of less than 200 mm and at a distance from any corner or vertical edge of more than 100 mm.

A single extraction duct may be shared by toilets, bathrooms, kitchens, and storage rooms.

Figure 3.1 Examples of ventilation inside housing

Kitchens, living rooms, bedrooms, and lounges must have a complementary system of natural ventilation. For this, a practicable exterior window or an exterior door must be provided.

Kitchens must have an additional specific ventilation system with mechanical extraction for the vapors and pollutants generated during cooking. For this, an extractor connected to a duct for extraction that is independent of the general ventilation of the dwelling must be provided, which cannot be used for the air extraction of premises of another use. When this duct is shared by multiple extractors, each must have an automatic valve that keeps its connection open with the duct only when it is operating or any other backflow prevention system.

Waste storage areas

In waste storage areas, a ventilation system must be provided, which can be natural, hybrid, or mechanical.

Means of natural ventilation

When the storage is ventilated through mixed openings, these must be provided at least in two opposite parts of the enclosure, in such a way that no point in the area is more than 15 m from the nearest opening.

When the storage areas are ventilated through intake and extraction openings, these must connect directly to the exterior, and the vertical separation between them must be at least 1.5 m.

Means of hybrid and mechanical ventilation

For hybrid ventilation, the intake openings must connect directly to the outside.

When the storage is partitioned, the extraction opening must be in the most contaminated compartment, and the intake opening(s) in the other(s), and passage openings must be provided between the compartments.

The extraction openings must connect to extraction ducts.

The ducts cannot be shared with premises of another use.

Storage rooms

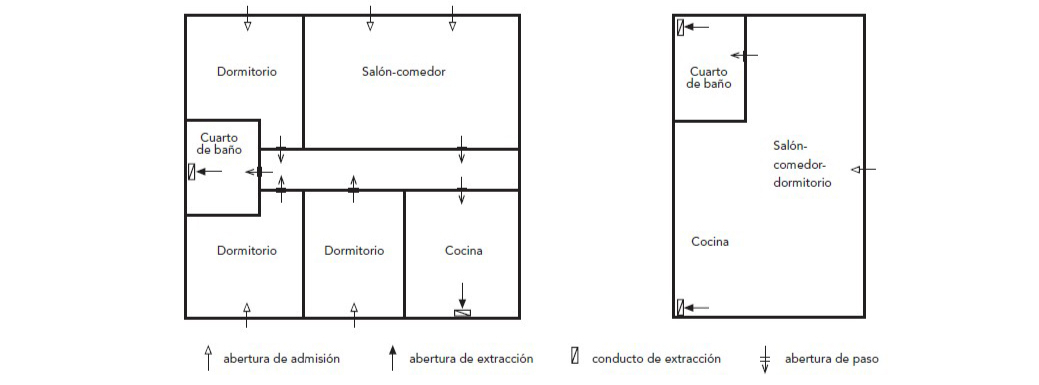

In storage rooms and their common areas, a ventilation system must be provided which can be natural, hybrid, or mechanical (see examples in figure 3.2).

Figure 3.2 Examples of types of ventilation in storage rooms

- Independent and natural ventilation of storage rooms and common areas.

- Independent ventilation of storage rooms and common areas. Natural ventilation in storage rooms and hybrid or mechanical in common areas.

- Dependent and natural ventilation of storage rooms and common areas.

- Dependent ventilation of storage rooms and common areas. Natural ventilation in storage rooms and hybrid or mechanical in common areas.

- Dependent and hybrid or mechanical ventilation of storage rooms and common areas.

- Dependent and natural ventilation of storage rooms and common areas.

Means of natural ventilation

Mixed openings must be provided in the common area in at least two opposite parts of the enclosure, such that no point in the area is more than 15 m from the nearest opening. When the storage rooms are ventilated through the common area, the partition between each storage room and this area must have at least two horizontal passage openings, separated vertically by at least 1.5 m.

Particular conditions for elements

Openings and ventilation mouths

In the absence of urban regulations governing their dimensions, the exterior spaces and the patios communicating directly with the premises through intake openings, mixed openings, or intake mouths must allow for a circle inscribing in its plan whose diameter is equal to one third of the height of the lowest enclosing wall and not less than 3 m.

They can use a ventilator or the existing gap between the doors and the floor as a passage opening.

The ventilation openings in contact with the exterior must be arranged in such a way as to avoid the entrance of rainwater or must be equipped with appropriate elements for that purpose.

The exhaust mouths must be located on the roof of the building, separated by at least 3 m from any intake ventilation element (intake mouth, intake opening, exterior door, and window) and from spaces where people may frequently be present, such as terraces, galleries, balconies, etc.

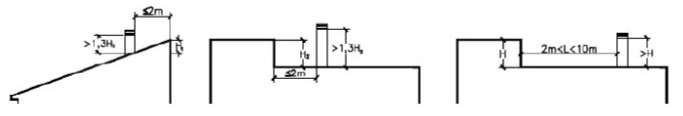

In the case of hybrid ventilation, the exhaust mouth must be located on the roof of the building at a height of at least 1 m above it and must exceed the following heights according to its placement (see examples in figure 3.4):

The height of any obstacle that is between 2 and 10 m away.

1.3 times the height of any obstacle that is at a distance of less than or equal to 2 m.

2 m on accessible roofs.

Inlet ducts

- The ducts must have a uniform cross-section and be free of obstructions throughout their length.

- The ducts must have a finish that makes them difficult to soil and must be accessible for inspection and cleaning every 10 m at most along their entire course.

Extraction ducts for hybrid ventilation

- Each extraction duct must have a hybrid fan located after the last extraction opening in the direction of the air flow.

- The ducts must be vertical.

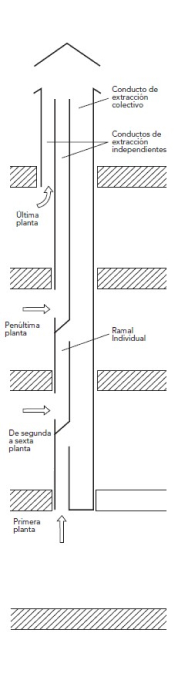

- If the ducts are collective, they should not serve more than 6 floors. The ducts of the last two floors must be individual. The connection of the extraction openings with the collective ducts must be made through vertical branches, each of which must lead into the duct immediately below the next branch (see the example in figure 3.3).

- The ducts must have a uniform cross-section and be free of obstructions throughout their length.

- The ducts that pass through fire sector separating elements must comply with the fire resistance conditions outlined in section SI1, paragraph 3.

- The ducts must have a finish that makes them difficult to soil and must be accessible for inspection and cleaning at the top.

- The ducts must be airtight for their sizing pressure.

Extraction ducts for mechanical ventilation

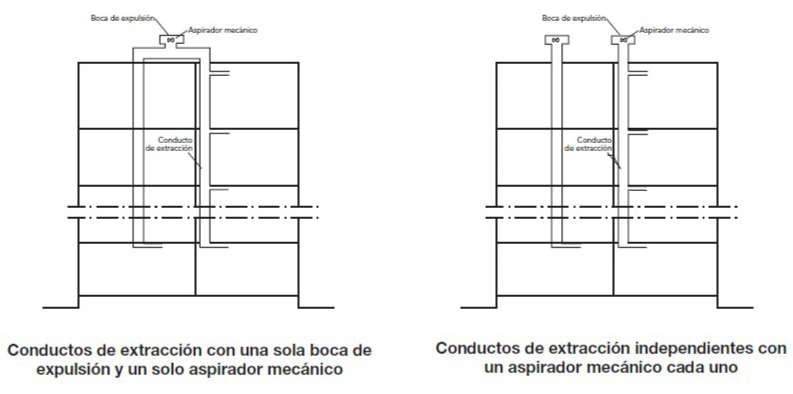

Each extraction duct must have a mechanical fan located, except in the case of specific kitchen ventilation, after the last extraction opening in the direction of the airflow, several ducts can share one fan (see the examples in figure 3.4), except for garage ducts when more than one network is required.

Figure 3.4 Examples of the arrangement of mechanical fans

Figure 3.5 Examples of ducts for specific additional kitchen ventilation

- The section of each section of the duct between two consecutive points with air intake or outlet must be uniform.

- The ducts must have a finish that makes them difficult to soil and be accessible for inspection and cleaning at the top.

- When it is expected that condensation temperatures may be reached on the walls of the ducts, they must be thermally insulated to avoid condensation.

- The ducts that pass through elements separating fire sectors must comply with fire resistance conditions outlined in section SI1, paragraph 3.

- The ducts must be airtight for their sizing pressure.

- When the duct for the specific additional kitchen ventilation is collective, each extractor must connect to it through a branch that must lead into the extraction duct immediately below the next branch (see the examples in figure 3.5).

Hybrid fans, mechanical fans, and extractors

The mechanical fans and hybrid fans must be located in an accessible place for cleaning.

Before the kitchen extractors, a grease and oil filter must be provided, equipped with a device indicating when it must be replaced or cleaned.

An automatic system must exist so that all hybrid and mechanical fans in each dwelling operate simultaneously or adopt any other solution that prevents backflow of air displacement at all points.

Exterior windows and doors

The exterior windows and doors provided for complementary natural ventilation must be in contact with a space that has the same characteristics required for intake openings.